TRANSPARENCY AND RELIABILITY IN THE VALUE CHAIN

ARTIFICIAL INTELLIGENCE

Ecotrace

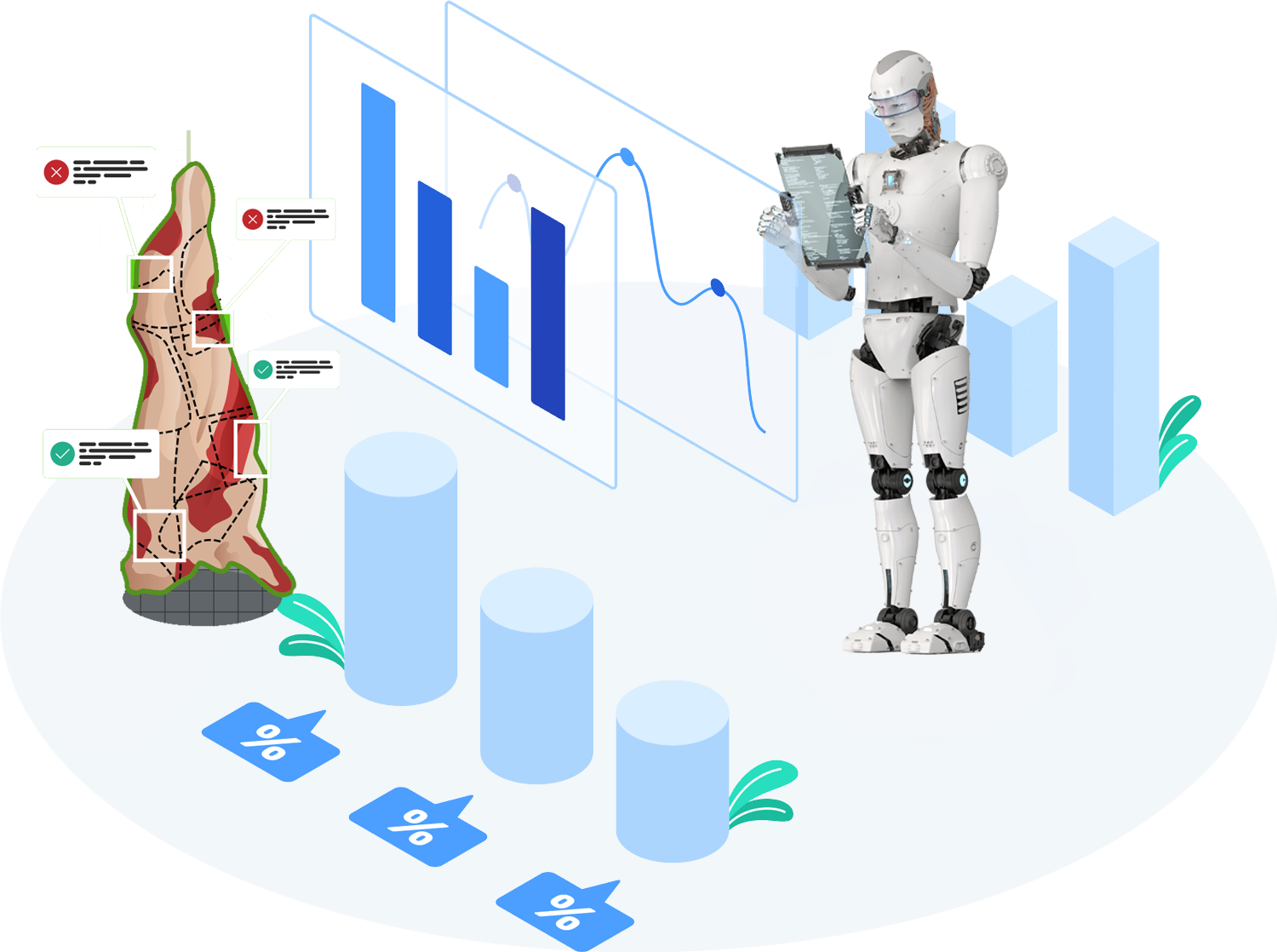

The ECO.IA Solution offers more reliability, assertiveness, precision, and standardization to the beef industry concerning the carcass grading system.

BENEFITS

FOR INDUSTRY

Increased assertiveness

of the carcass grading system

50% improvement

in the accuracy of production data

Standardization

in the carcass grading system among the units of the group

Appointment

in real-time, with notes in the region of the cuts mapped on the carcass

BENEFITS

FOR INDUSTRY

Increased assertiveness

of the carcass grading system

50% improvement

in the accuracy of production data

Standardization

in the carcass grading system among the units of the group

Appointment

in real-time, with notes in the region of the cuts mapped on the carcass

ARTIFICIAL INTELLIGENCE ECOTRACE

TO AUTOMATIZE THE CARCASS GRADING SYSTEM

PRODUTOR

Canal digital para acesso aos dados do abate com evidências e transparência

INDÚSTRIA

Automação com IoT e Inteligência Artificial para acompanhamento de processos industriais

VAREJO

Soluções online para garantia de origem.

Transparência e confiança na cadeia de valor

A new technology to automate carcass grading system in your operations that will optimize slaughter data accuracy!

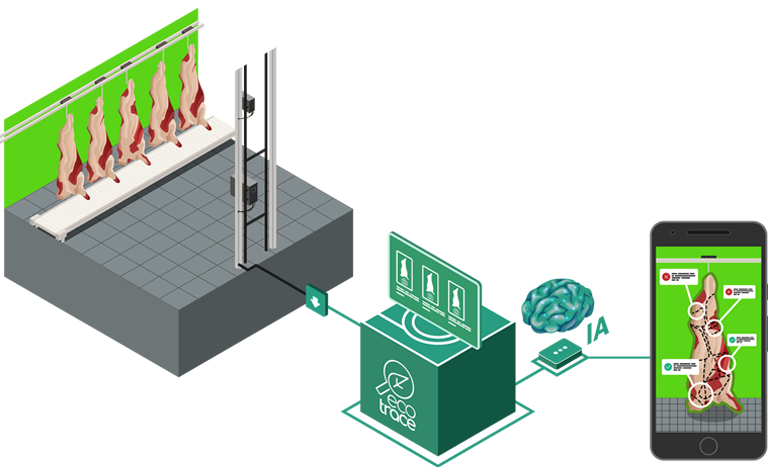

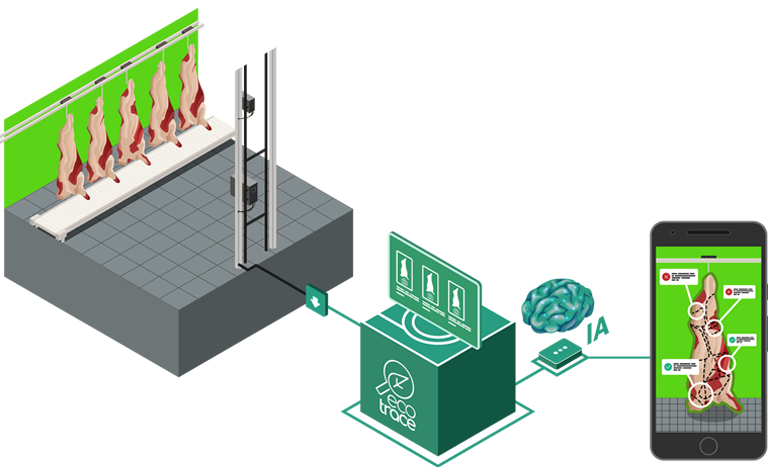

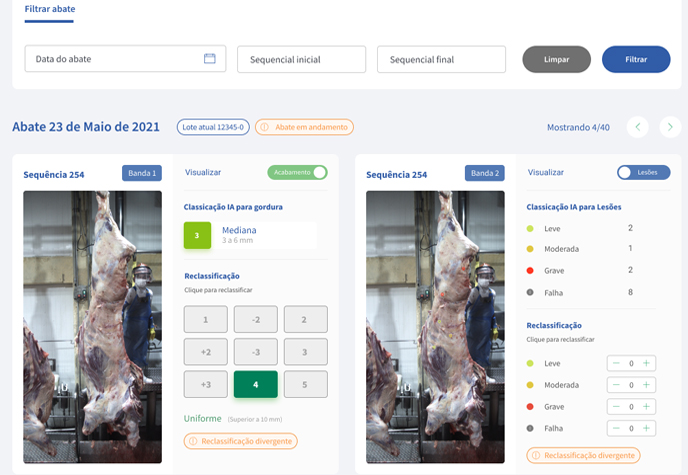

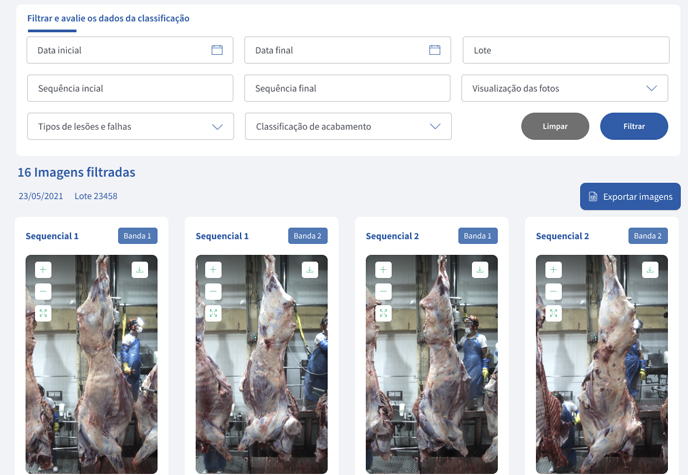

It´s a real-time new process of carcass grading system by artificial intelligence for the slaughterhouse. The process can analyze carcasses images collected in the slaughter process through specific cameras installed in the beef industry and shows in real-time mapping of cuts on the carcass in a more agile and precise way.

With this innovation, each half-carcass image is evaluated and graded, on average, every 0.8 seconds.

The solution wants to eliminate the subjectivity of the grading process, improving the classification standard system with technologies like IoT and Artificial Intelligence. In addition to the grading carcass beef, the system also identifies bruises and operational failures by beef cuts.

Optimize your operation and make your production more assertive and standardized, from the choice of suppliers to the final product!

ARTIFICIAL INTELLIGENCE ECOTRACE

TO AUTOMATIZE THE CARCASS GRADING SYSTEM

PRODUTOR

Canal digital para acesso aos dados do abate com evidências e transparência

INDÚSTRIA

Automação com IoT e Inteligência Artificial para acompanhamento de processos industriais

VAREJO

Soluções online para garantia de origem.

Transparência e confiança na cadeia de valor

A new technology to automate carcass grading system in your operations that will optimize slaughter data accuracy!

It´s a real-time new process of carcass grading system by artificial intelligence for the slaughterhouse. The process can analyze carcasses images collected in the slaughter process through specific cameras installed in the beef industry and shows in real-time mapping of cuts on the carcass in a more agile and precise way.

With this innovation, each half-carcass image is evaluated and graded, on average, every 0.8 seconds.

The solution wants to eliminate the subjectivity of the grading process, improving the classification standard system with technologies like IoT and Artificial Intelligence. In addition to the grading carcass beef, the system also identifies bruises and operational failures by beef cuts.

Optimize your operation and make your production more assertive and standardized, from the choice of suppliers to the final product!

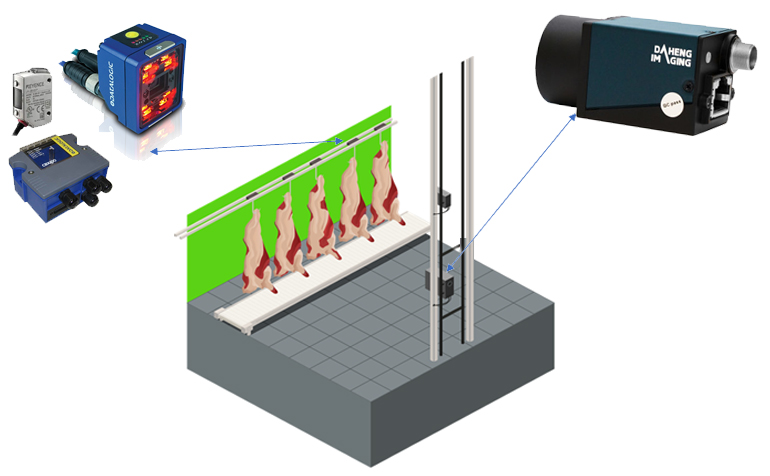

ARTIFICIAL INTELLIGENCE ECOTRACE:

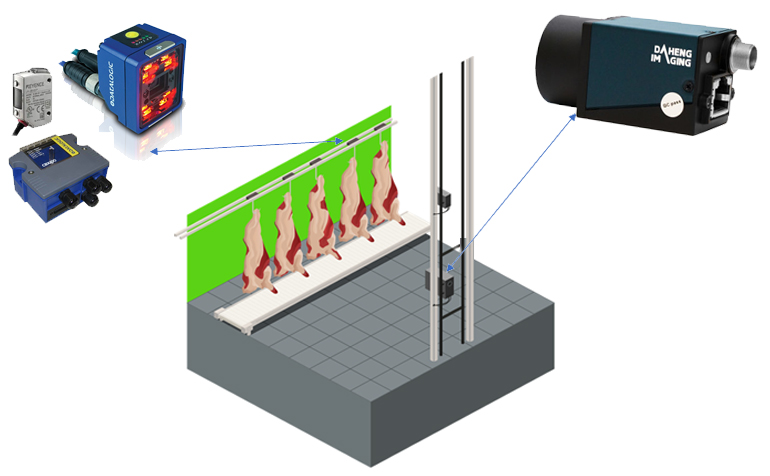

HOW IT WORKS

Inteligência Artificial Ecotrace

Processo de

captura das imagens

Processo de

captura das imagens

COMPUTATIONAL

VISION

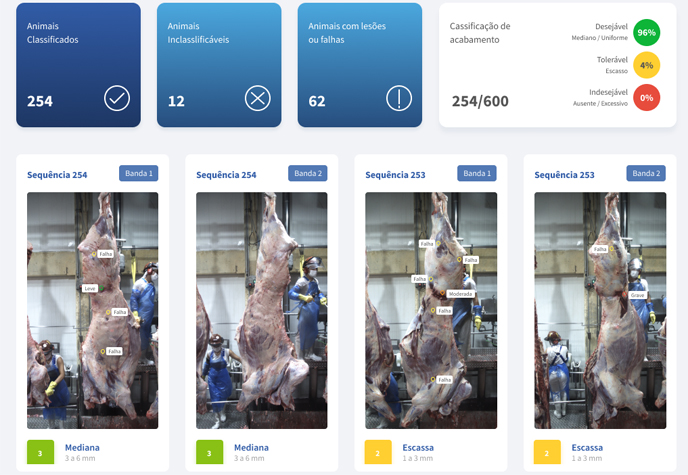

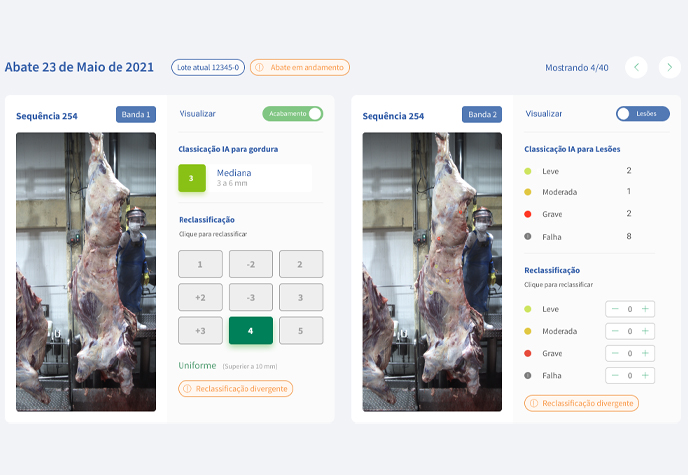

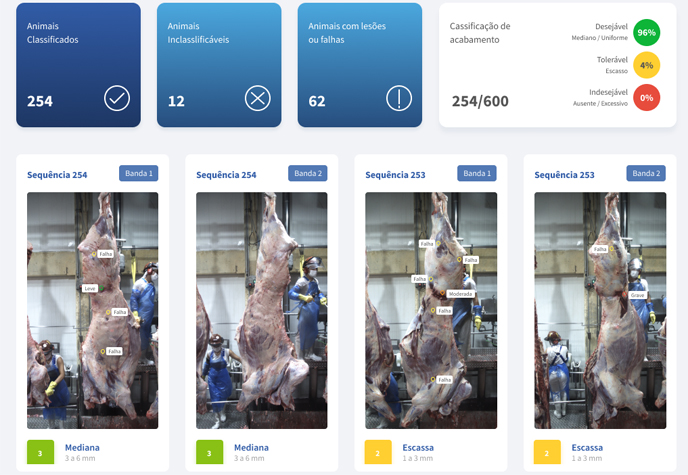

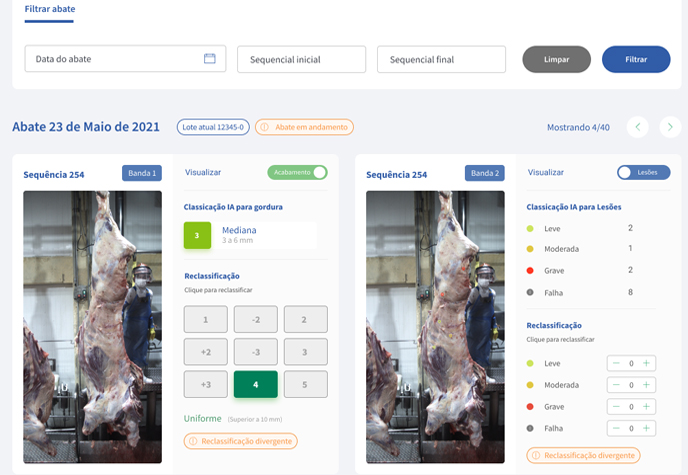

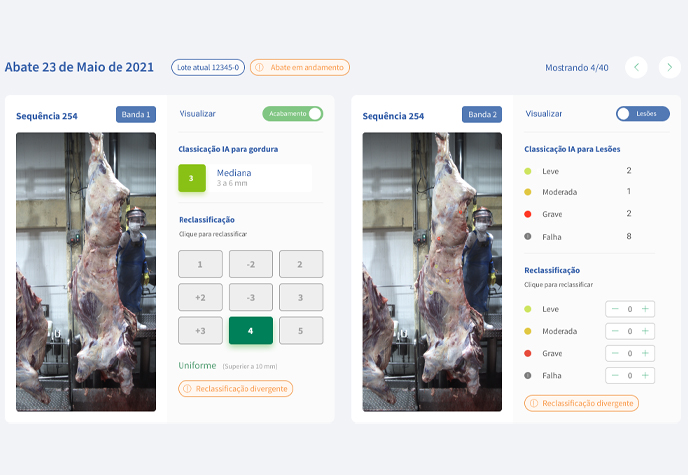

Grading carcass beef system and appointments of bruises and operational failures on the carcass.

ARTIFICIAL INTELLIGENCE ECOTRACE

HOW IT WORKS

COMPUTATIONAL

VISION

Grading carcass beef system and appointments of bruises and operational failures on the carcass.

Software

ECO.IA

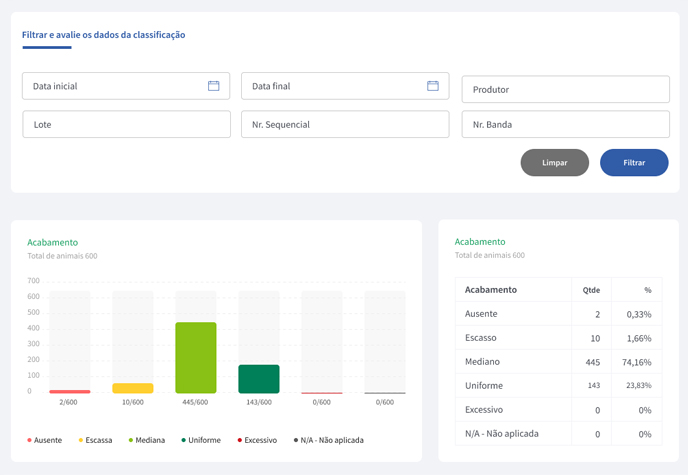

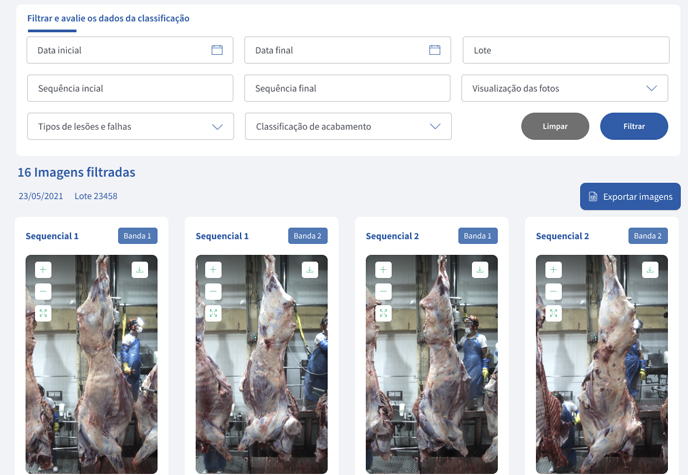

Display panel with grading carcass and appointments of bruises and operational failures in real-time for monitoring slaughter data.

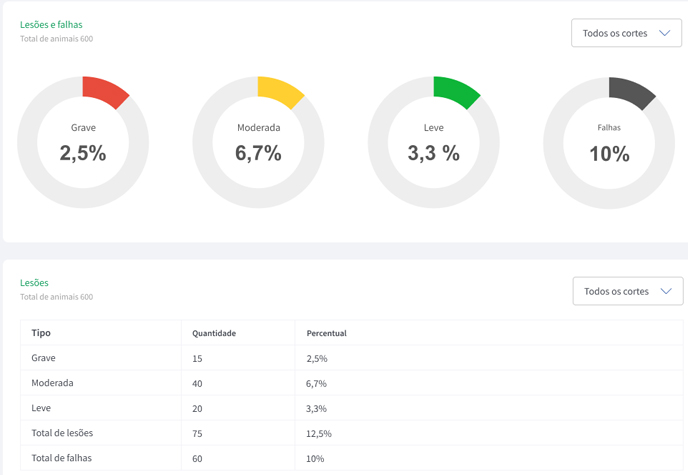

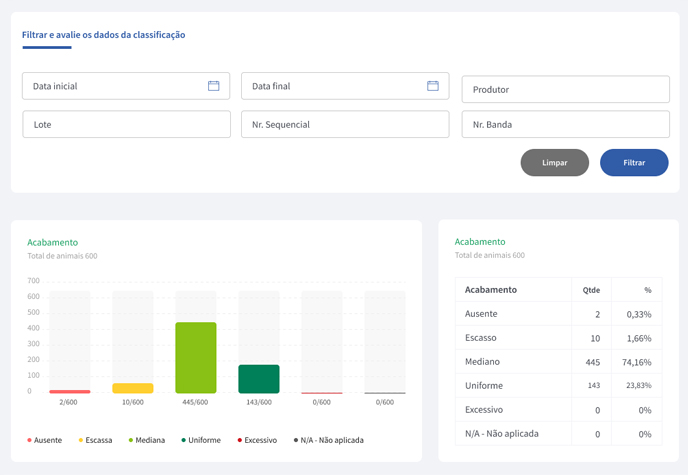

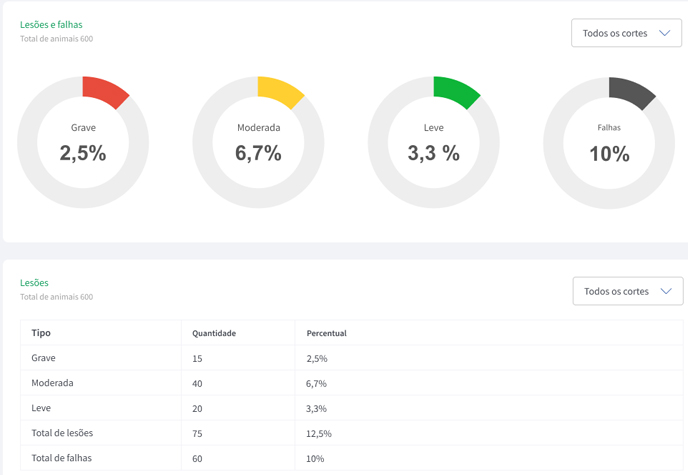

Reports with details of each carcass electronically identified in the system, with a list of levels of bruises. Charts with all relevant slaughter indicators by day or producer.

Software

ECO.IA

Display panel with grading carcass and appointments of bruises and operational failures in real-time for monitoring slaughter data.

Reports with details of each carcass electronically identified in the system, with a list of levels of bruises. Charts with all relevant slaughter indicators by day or producer.

know more

Blockchain-based end-to-end commodities traceability platform. We focus on agro, founded by entrepreneurs combining more than 20 years of experience in agribusiness and technology. We offer a unique end-to-end traceability solution, ensuring reliability, security, and transparency across the value chain.

Technology assisting industry.

All carcasses are classified with Artificial Intelligence algorithms, using the EcoIA module, thus bringing more transparency to the processes. All algorithms are proprietary. 100% auditable system.

The entire process within the meat processing industry, from the arrival of the animals to the final weighing, is monitored by the Ecotrace platform. This process does NOT replace the current system used in the industry, but works in parallel, through communications using web services between the systems.

Total transparency to the Farmer, returning information for a better analysis of the production process.

Empresa FOCADA NO AGRO, constituída por empreendedores com mais de 15 anos de experiência no agronegócio, oferecendo uma solução de rastreabilidade única, trazendo confiança, segurança e transparência em toda cadeia de valor, atuando desde a origem até o consumidor final.

Tecnologia auxiliando a indústria.

Todas as carcaças são classificadas com algoritmos de Inteligência Artificial, utilizando o módulo EcoIA, trazendo assim mais transparência para os processos. Todos os algoritmos são proprietários. Sistema 100% auditável.

Todo o processo na indústria frigorífica, desde a chegada dos animais, até a pesagem final é monitorado pela plataforma Ecotrace.

Esse processo não substitui o sistema atual da indústria, mas funciona em paralelo através de comunicações utilizando webservices entre os sistemas.

Total transparência ao produtor, retornando as informações para uma melhor análise do processo produtivo.

SUBSCRIBE

JOIN THE

AGRO REVOLUTION

Fill in the form, and our team of experts will get in touch with you!

IF YOU PREFER, CALL:

SUBSCRIBE

JOIN THE

AGRO REVOLUTION

Fill in the form, and our team of experts will get in touch with you!

IF YOU PREFER, CALL:

- +55 (19) 2660-2778